Inkjet Addendum

Inkjet addendum:

On taking the position of engineering project manager for printheads, I was the technical leader in printheads in Corvallis. As such, I played a role in getting ink jet started in Corvallis and in managing its success as a business. I never verified the facts but a leader in ink jet claimed that the growth rate in the years 1989 to 1998 exceeded the growth rate of Microsoft in its peak period, which was considered an example of very successful businesses. I will cover a more detailed story of my experiences in ink jet here than in the main story.

I previously mentioned my working with Bob Waites in Cupertino while I was learning the printhead technology. After the move of printheads to Corvallis, Bob took a position in HP labs in Palo Alto and he and I talked occasionally on the phone during the start up in Corvallis. In 1978 he called me and told me about a printing technology called ink jet that Jon Vought in HP labs was working on and suggested that I take a look at it as a possible replacement for thermal printheads. Thermal printheads had some well-known shortcomings: one was they were inherently very slow in printing speed. A second was the inherent low resolution. The third was they required special, expensive paper. So, a better technology was definitely of interest to me.

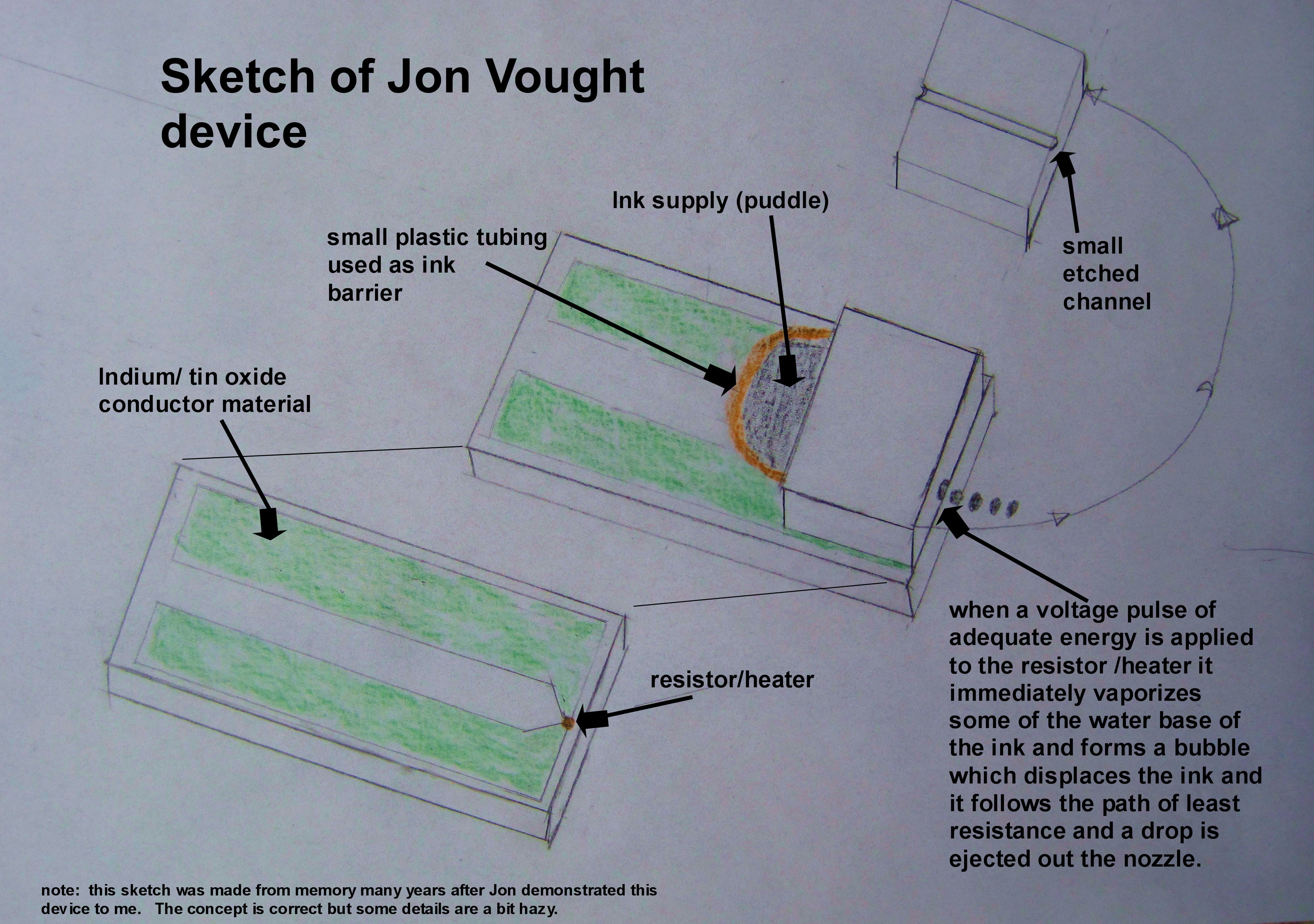

I had hired Ken Trueba to manage the HP85 printhead and he was going to Palo Alto for some reason, so I told him to stop by and see what Jon was working on. He came back enthused. Jon's device was very simple and he was able to demonstrate it by shooting drops on one of his business cards. So, I called Jon up to set up a demo and he told me he was planning an I to L review and it would work out well if I went to that and then he demonstrated it to me. So I went. An I to L review was a check point to move an idea from the purely investigative phase to a phase where you tried to build a prototype of a potential product. The HP labs manager was legendary Barney Oliver. He was long time manager of HP labs, notorious for being fearlessly outspoken and asking hard questions. I had heard much about him but had never met him. He turned out to be pretty impressive. A huge man physically and dominant in any meeting. For this I to L he sat in the middle of a relatively small, theater like presentation room and was definitely the focus for the presentation. I was one of about half a dozen others attending and Jon Vought was making the presentation. Barney Oliver was interested and insightful and asked all of the questions I had and more. In the end, he turned to me and asked if we were interested enough to share in the expenses of the lab prototype phase. Of course, I didn't even report to the Corvallis R&D department, let alone have authority to commit resources, so I told him I was very impressed with the potential for the technology to fit in the future printing for calculators and I would present this to the Corvallis R&D manager. I visited with Jon and he demonstrated his printing device.

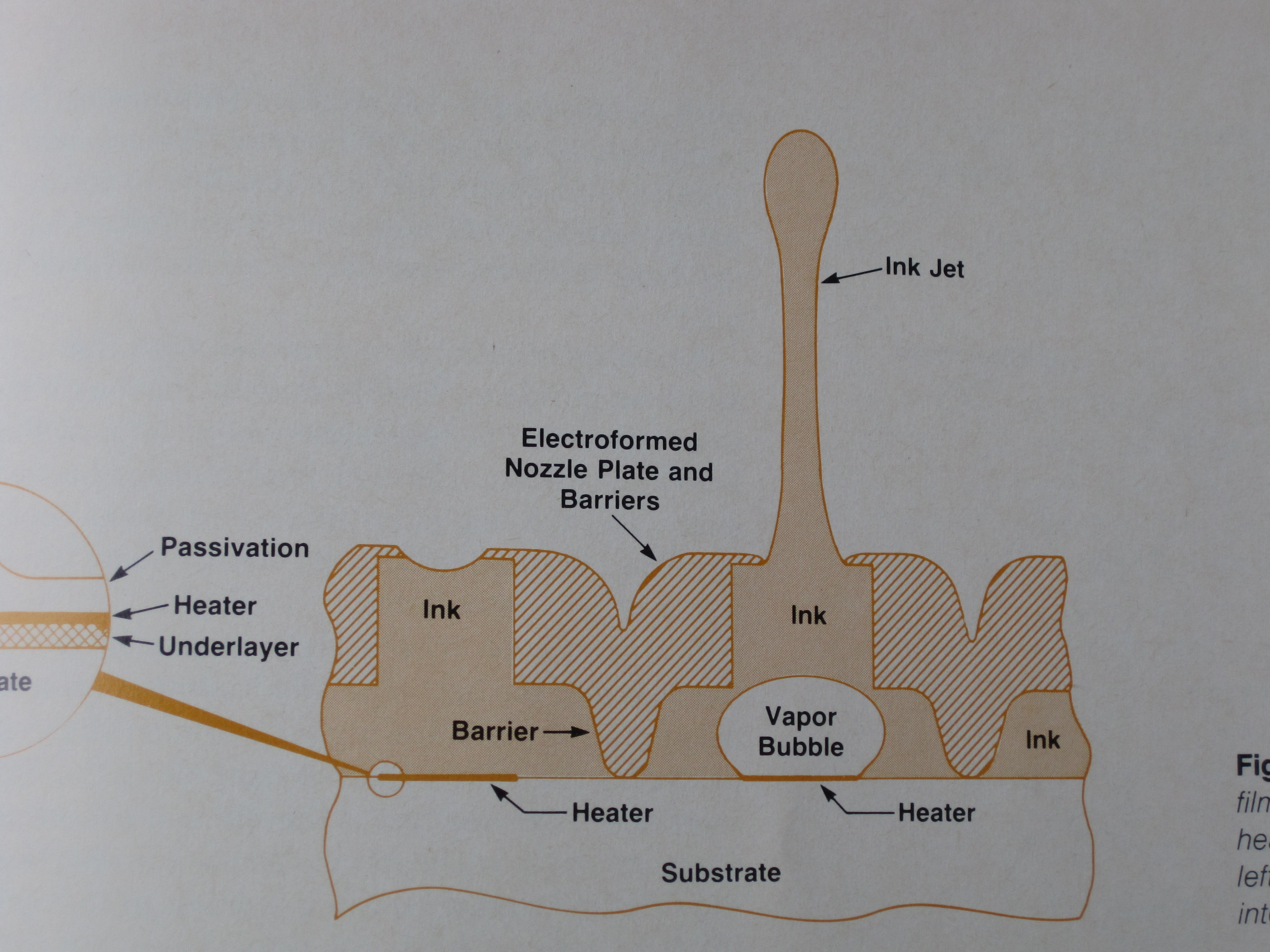

It consisted of a base plate of glass that was coated with indium-tin oxide and etched to form a single resistor near the edge. Over this was glued a microscope slide which had a very small (~25 micron) groove cut all the way across it. The slide was placed even with the edge of the base plate and the slot was placed over the resistor. An ink reservoir was created next to the inside edge of the slide and the water-based ink wicked down the slot and covered the resistor. When an electric pulse was applied to the resistor, the ink above it super heated and boiled and the expanding bubble forced an ink drop out the end of the slot. By applying a train of electric pulses, he could create a series of drops and when he pulled his business card through it left a line of dots. I was impressed.

I returned to Corvallis and wrote up a project proposal listing all of the advantages I saw for thermal ink jet technology over the thermal printhead technology. I didn't begin to imagine all of the advantages that would evolve but it was obviously a technology well suited in the future of hand-held calculators, which was the Corvallis business. I personally presented it to the R&D manager. He took my copy and never mentioned it again.

In 1979 the manager of the Corvallis Components Operation, Ed Shidelar, started enlarging his operation in hopes, I suspect, of becoming a division manager. His primary move was to create an R&D department and he hired Ernst Erni for his R&D manager. Ernst inherited several engineering groups from around CCO to form his R&D department, including the old LCD development group. The LCD program had been abandoned when Hitachi came over and clearly convinced calculator management that we were hopelessly behind the LCD development in Japan. Ernst's first move was to request anyone interested to submit a project proposal and from these he would choose what his group was going to work on. So, of course, I dusted off my inkjet proposal and updated it and submitted that. It was never explicitly stated but was widely understood that whoever submitted a proposal would be the one to manage it. Frank Cloutier, a friend of mine who had originally worked on a thermal printhead project in Loveland, Colorado and had transferred to Corvallis to work on the LCD program, submitted a proposal for an active device LCD. (Active LCDs were/are LCDs with the driver electronics on board which is the basis of the high-density television displays that have taken over in recent years). Ernst chose my ink jet proposal. However, Ernst was not the type to forget a grudge and he definitely still held a grudge against me for standing up to him in front of Ed Shidelar. So, he chose Frank to manage the ink jet project.

I believed so strongly in the ink jet technology that I was going to talk to Frank about working for him (which would have been a demotion). However, at about this same time Printhead manufacturing got a new manager, Greg Merten. Greg had been promoted at some division in the bay area as the youngest Manufacturing manager in HP. However, things hadn't worked out and after a few years he was replaced and given the job in Corvallis as a landing spot. As printhead manufacturing manager, he was my boss. I told him I planned on going to the new R&D group to work on ink jet and he asked me if I would stay a year to help him learn the printhead business and after that year he would insure I got a spot on the inkjet project. I agreed and spent the next year working on and teaching him about printheads. One other person was given a landing spot after falling out of favor with his managers in Loveland, and that was Tom Haswell. He was still waiting for a job and he was given a desk next to mine. Whenever I was available, he picked my brain on printheads, people and whatever else interested him. This friendship paid off later. When the year was up, Greg was true to his word and I moved into Frank's group.

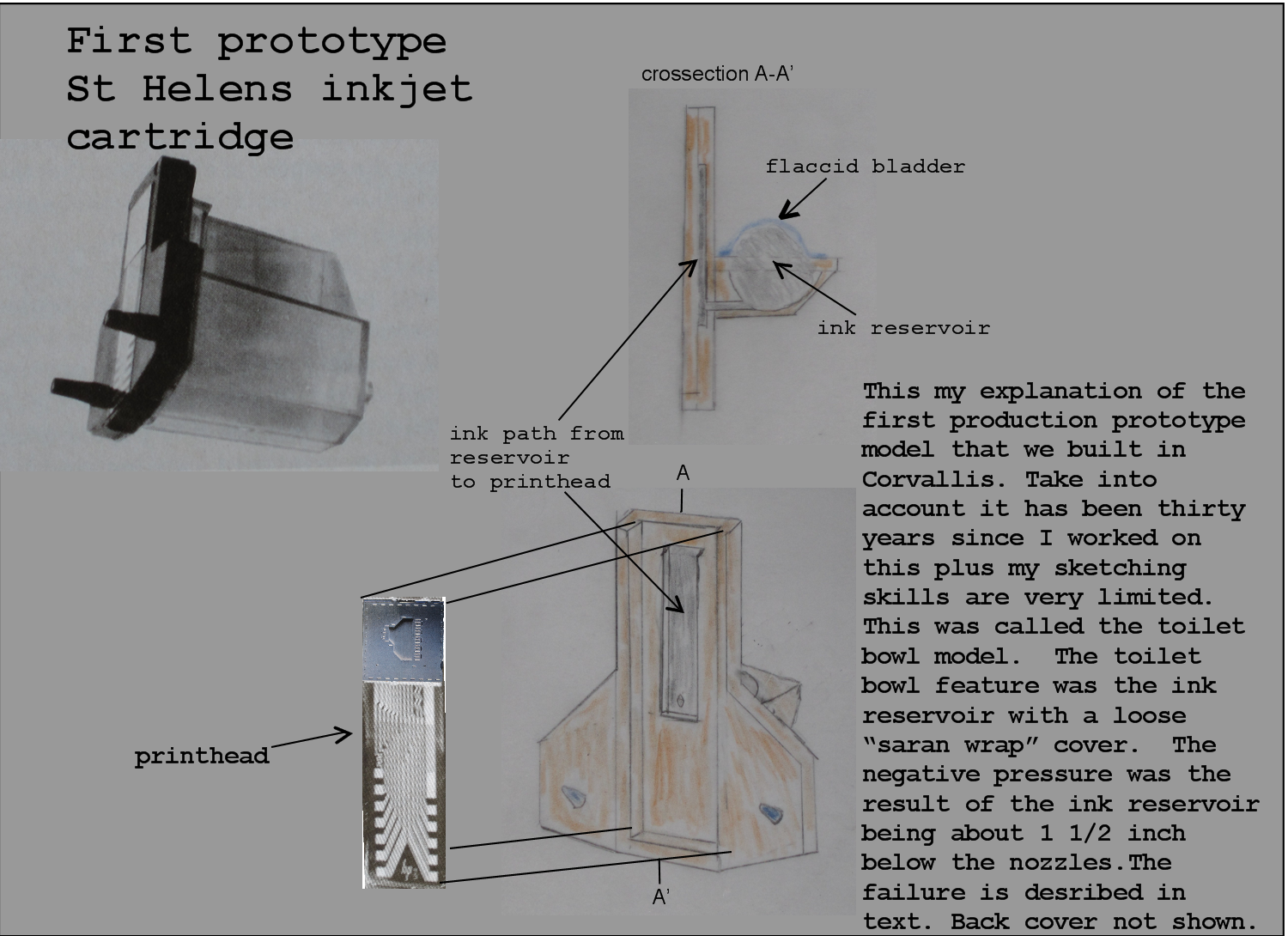

During the year I stayed in printheads, Frank and a group of five or six engineers worked on trying to develop a product prototype. They had made a couple of significant advances. One was they decided on a product that was 12 dots in a line at 96 dpi resolution. They also conceived of the concept which they termed the "orthogonal shooter". Jon Vought's design had fired ink down a channel and out the end of the channel, essentially in line with the channel. The orthogonal idea was to build a channel closed on the ends and with a hole (orifice) pointing 90 degrees to the channel. They had also conceived of an overall product configuration and had tried to build a prototype with limited success; i.e., they had built one device which did shoot drops and they were able to print characters with it. Neils, one of Frank's engineers was so excited that when he heard John Young was visiting Corvallis he drove out to the airport and met John Young as he came off the plane and shoved this print sample in his face. It was not the best marketing move. John Young didn't know who this nut was nor what he was jabbering about. But Frank was an excellent promoter and he kept management funding the project and believing it had potential. I joined the group in 1980 and Frank divided his team into two parts: Marzio Leban was the project manager responsible for developing the thin film processes and providing the conductor and resistor network on a glass substrate. I was project manager for everything else, which included the orifice plate, attaching the orifice plate to the thin film substrate, the ink, the ink containment, the plastic pen body, testing and print quality measurements. This seems daunting, and it was, but as the project progressed, I developed different teams (i.e., Assembly, Ink, Testing) and these were split off and managed separately from me, except for the orifice plate.

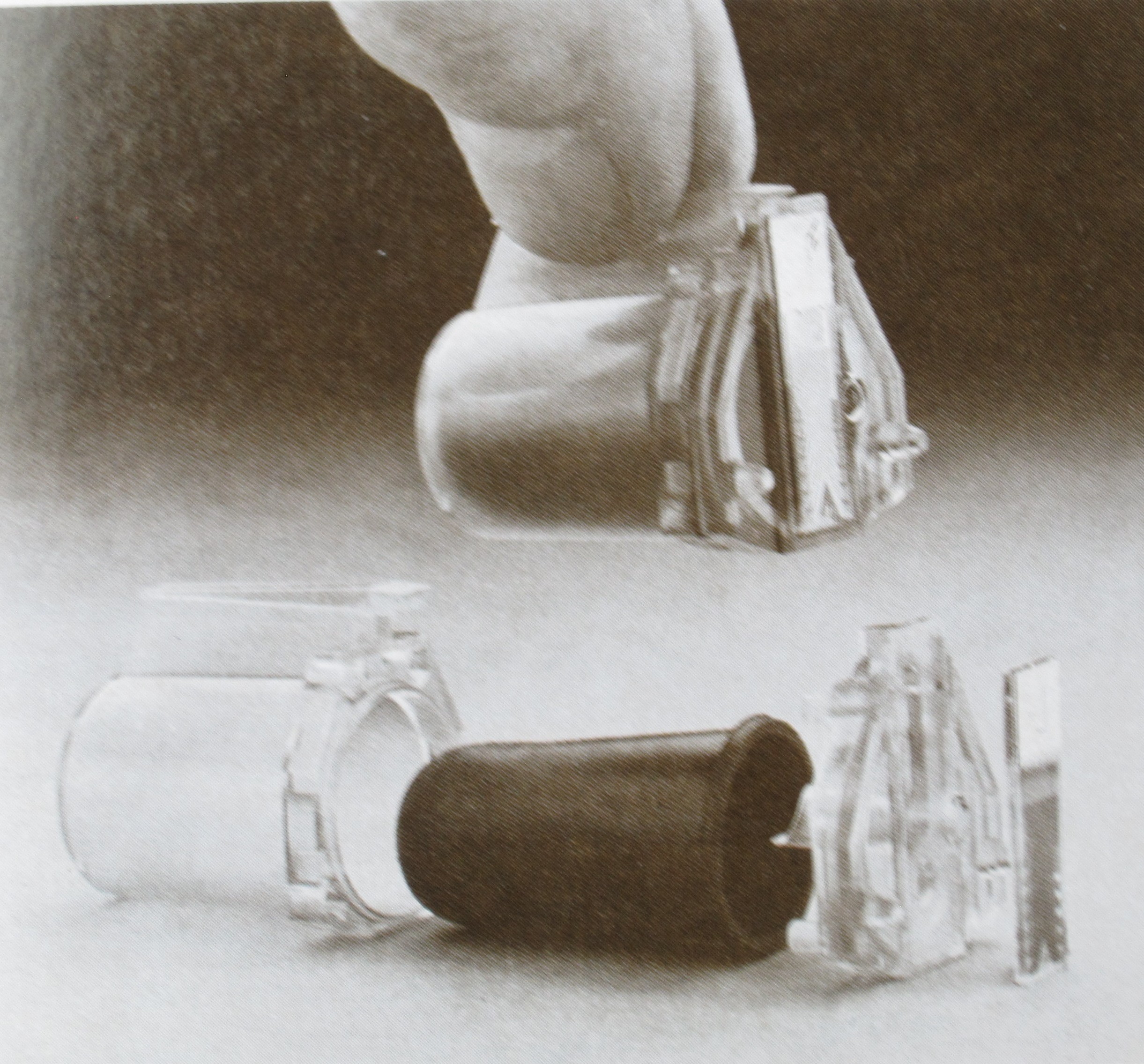

The concept the engineers developed in that first year for ink containment was what they called a flaccid bladder. It was basically loose saran wrap sealed to a commode shaped feature on the plastic pen body. The idea being that the bladder would collapse as the ink was used and not create back pressure, somewhat like a baby bottle. The glass substrate was sealed to the opposite side of the plastic pen body and a hole was drilled through the glass to allow the ink to flow into the firing chamber. Drilling the hole in the glass was also added to my responsibilities.

We were able after a few months to put together some working prototypes. I inadvertently discovered one of our early problems. I had several of these prototypes sitting in a clear plastic box on my desk and after a couple of weeks the ink started oozing out the nozzles. I also noticed that the bladders were tight. After some research on the cause, I concluded it was due to pressure build up explained by Dalton's Law which states that the pressure of a mix of gases is equal to the sum of the partial pressures of each independently. What was happening, I concluded was that the gases in the atmosphere were all diffusing through the membrane and their partial pressures were equal to atmospheric pressure. However, the ink was water based and the atmosphere inside the ink chamber was saturated with water vapor which pushed the pressure above atmospheric pressure and pushed the ink out through the orifii. A second discovery someone made was that if we shocked one of our printheads just right, like tapping it on something, it would start ink flowing out through an orifice and it would continue, i.e., drool. The only thing holding the ink in under normal conditions was the surface tension at the exit of the orifice. If something caused the contact angle to go positive, there was no restoring force. We had a serious ink containment problem.

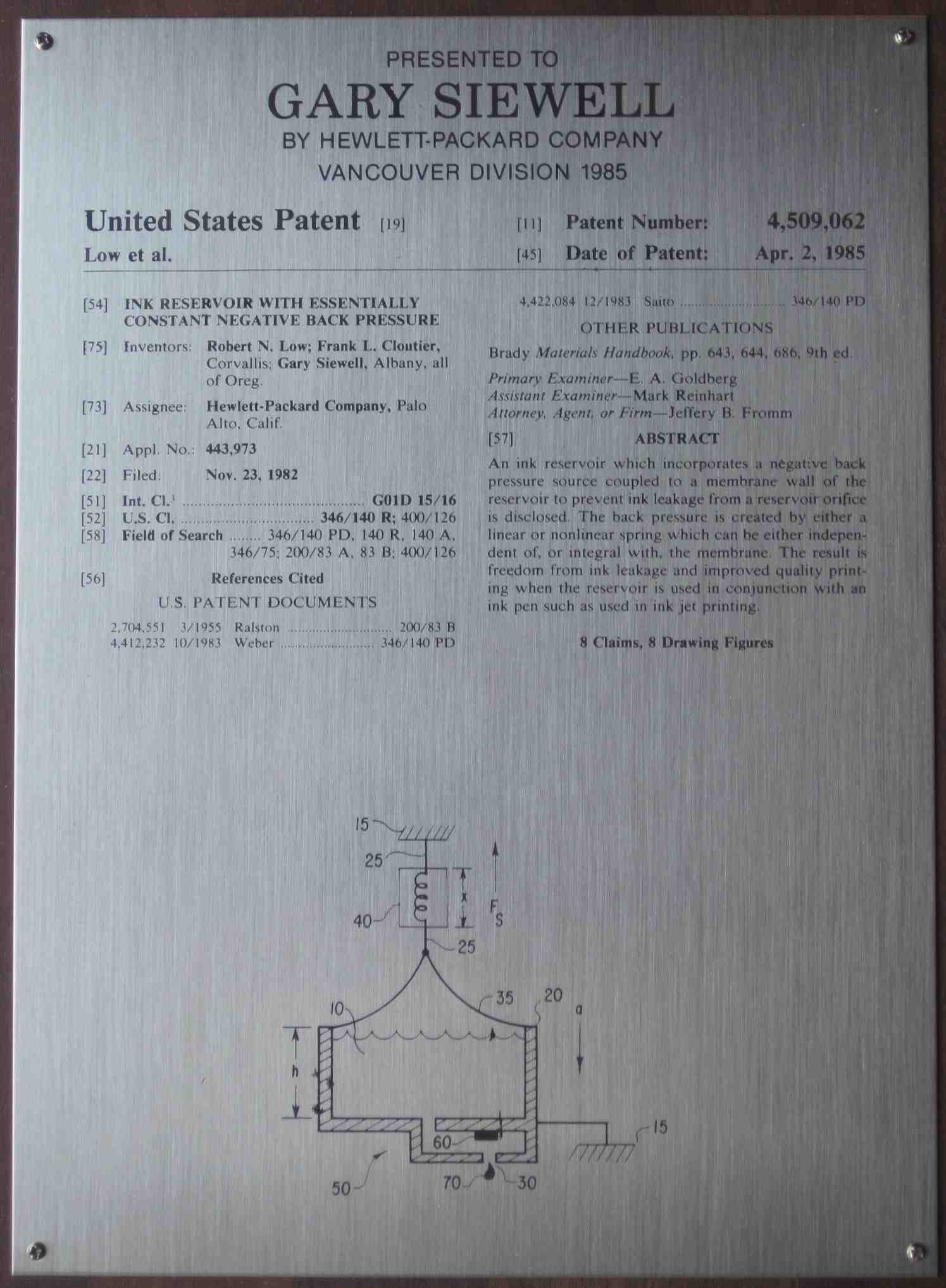

I put together a team of Bob Low, Niels Nielsen, and I (with unsolicited help from Frank). It was clear we needed some negative backpressure to hold the ink in and it also was made clear early on by Niels that too much backpressure negatively affected print quality. Niels had used a u-tube manometer to measure different pressures and raised and lowered the head to change back pressure as he measured the print quality. We were talking a few inches of backpressure (1 Atmosphere = 407 inches of water). We had several brainstorming sessions which included other engineers from around the Division we thought could contribute. We came up with three viable ideas: foam, a stiff bladder like those once used in fountain pens, and a mechanical spring to tug on the bladder. San Diego had used foam to contain ink in the fiber tipped pens used in their plotters, so we picked their brains on foam. Bob attacked the stiff bladder which was primarily a problem of material selection. Frank worked on his mechanical spring idea. Bob came through with a stiff bladder shaped like a thimble (I think of polypropylene) that solved the problem and we settled on it. The shape and thickness determined the backpressure and we optimized that and moved on. At a much later date we applied for and received a patent on this backpressure control. It congealed my thoughts on inventions (or patents) that very rarely are they the result of one individual's brilliance but most often are the result of the inputs of a team just doing what they are paid to do. Patent holders are much overrated.

An aside: Recently (2016) my niece Marsha, Gilbert's daughter, said she had googled me and read about my patents. I dismissed it with the overrated comment above but then decided maybe it needed elaboration. Patents are not insignificant and they do typically represent some good and creative work. My problem with them is that usually they either get associated with one person (ala Edison) or the wrong person (ala Edison). Almost all, if not all, progress in technology is the work of teams of people and most of them contribute important aspects to the progress but few show up on the patent. It is extremely doubtful that Edison sitting all alone at his workstation had this sudden and brilliant idea to create light by heating up a filament. Much work had no doubt gone on before, even before Edison got interested in light, and even his work was likely the work of him and assistant(s). As they encountered problems, they discussed them and threw out possible solutions and then tried the most promising and adapted the successful until finally there was light. As head of the team, Edison applied for and got the patent and the glory. We will never know who on his team came up with the idea that solved the most crucial problem. I was involved in a lot of research in my career and I saw many times how this process worked. At Tektronix the intellectual properties were protected by having everyone involved in research keeping detailed and verified logbooks. Earlier HP had done the same but with inkjet they decided to protect it with patents. So, an example is the case of our solution of the backpressure problem above. As head of the team, I held meetings regularly and we discussed the problems encountered with all of the potential solutions. I called in engineers from other areas that I knew had special expertise we needed. We discussed solutions, with no one standing out in my mind as contributing more than others. Certainly, Bob and Neils and I were closest to what was happening with Bob and Neils doing the experimental work and I was ultimately responsible for the solution. The chosen path of a bladder was one that Bob had done the experimental work on. The concept came from the bladders used in old fountain pens and this being the day of ballpoint pens I was the only one of the three who had used the old fountain pens so the idea came from me. The point is that these types of invention are the work of many, not one. The closest I came to an original, significant idea that became a patent didn't end up with my name on it. While developing the TRIAD pen we encountered a problem with particulate contamination coming through the ink and clogging up an ink channel and killing the nozzle. The engineer assigned was Bill Boucher and he undertook the standard approach, try to clean up the assembly. This was not working. There was an electroformed wire screen between the ink reservoir and the entry hole in the printhead. This mesh was attached to the ink reservoir. I was thinking about ways to have multiple, redundant ink paths to the nozzles and it occurred to me that we might be able to make something akin to this mesh out of the photo definable material we used to define the ink channels on the printhead. The concept was to have a series of posts along the edge of the thin film substrate that the ink would pass thru prior to entering the individual channels of each nozzle. I sketched up the idea and told Bill to talk to the process engineers working on the processes that defined the channels and get them to try this. Bill was not very enthused and the process engineers didn't want more work so Bill reported to me that the process engineers said it was not feasible with the materials we had. I was dubious and displeased but I had too many other issues to get more involved so I dropped it. A year or so later, I was manager of the color line of cartridges and Paul Harmon was my engineering manager. He was looking for projects that would improve quality or lower costs of our cartridges and I suggested he consider this idea. His team also initially rejected it, but I had more clout and insisted they take it at least thru a feasibility stage. So, they reluctantly tried it and were amazed at the results. To give an idea of the significance I will attempt to revive my statistics. I have forgotten how many nozzles TRIAD had but it was 300 dpi and the nozzles were probably about 1/6 inch so 50 nozzles is a good estimate. To be a substantial problem at start up the defect rate (one nozzle plugged was a defect) would have to have been around 10%. So, the probability of one plugged channel was 1/10 and the probability of a particular channel being plugged was 1/10 X 1/50 = 1/500. So, by just providing one redundant path for each nozzle the probability of a defect (two adjacent channels plugged) would be 1/10 X 1/500 or 1/5000. So, the defect rate was lowered from 10% to .02%. (My statistics is worse than rusty so research it and check it, it will do you good!) Subsequently a program was executed to put it in all cartridges. After it was implemented the engineer, Tim Webber, who had done most of the work transferred to R&D. While there he applied for the patent and did not put my name on the patent. I was even more incensed when I found out HP had a new policy of a $1000 for patents. So, patents are significant achievements but not always what they appear to be.

Now back to inkjet development.

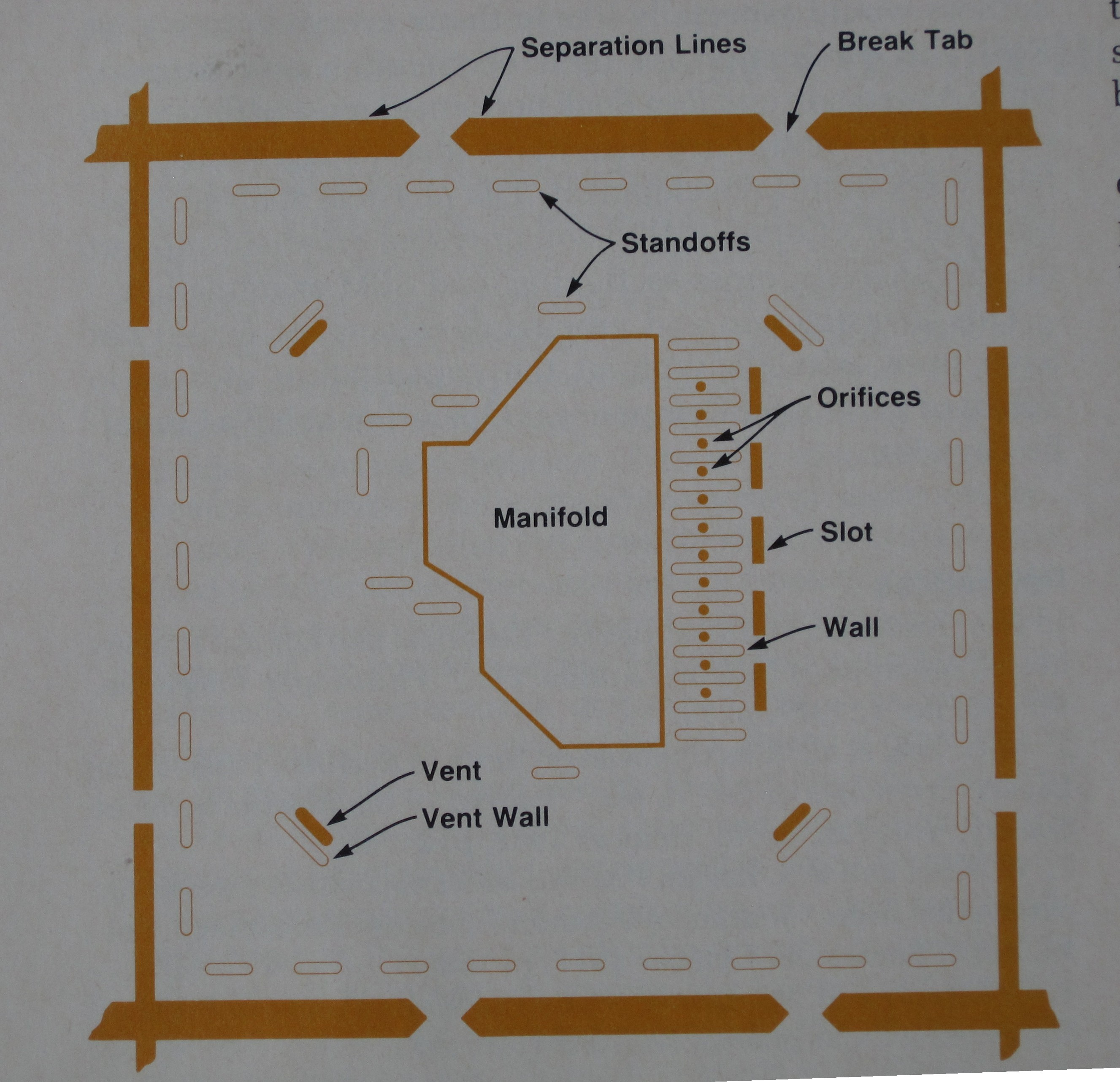

The challenge that was recognized as the most daunting from day one was the fabrication of the orifice plate.

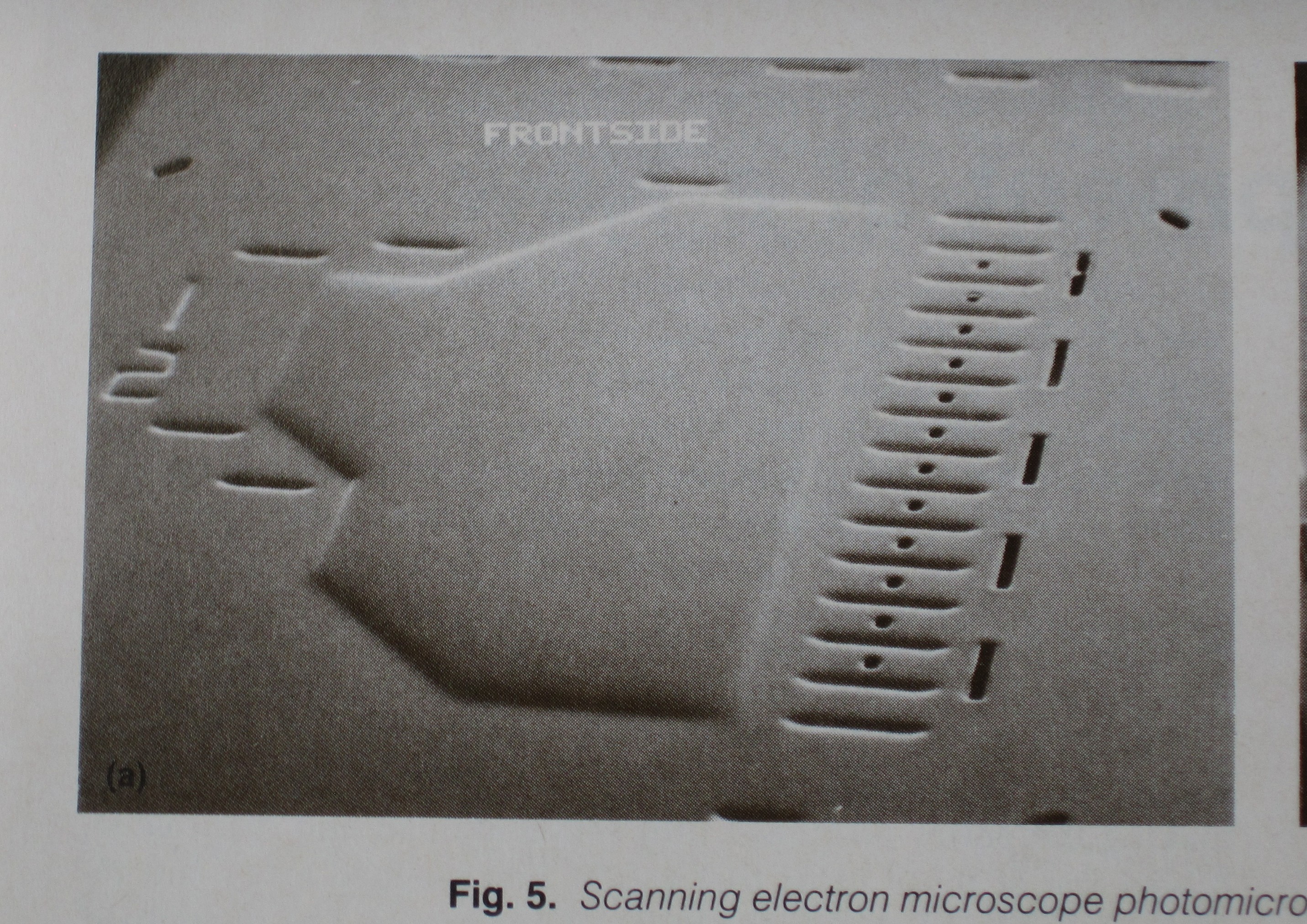

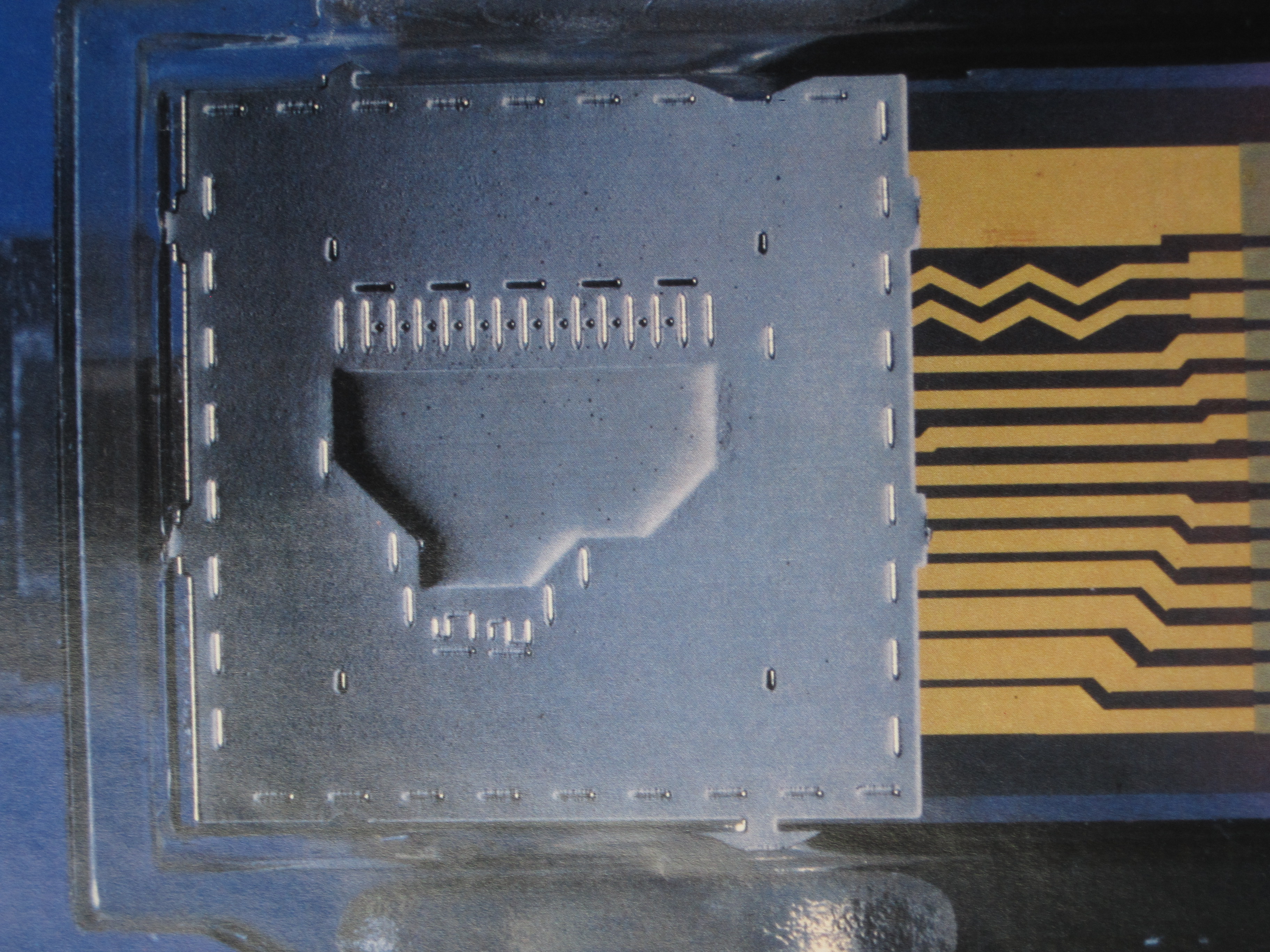

There were several features of the orifice plate: it first of all was to be about 20 microns thick and it had a row of twelve orifice that were about 20 microns in diameter at the exit and were on 96 dpi spacing. In between each of these orifices was a barrier that kept the firing of one resistor from shooting drops out adjacent orifice. And third it had to be sealed to the glass substrate at a precise distance (about 30 microns) and it served as ink containment. The spacing was established by the height of the barriers and was part of Mazio's responsibility. Paul McClelland was the engineer assigned to orifice plates. Paul's concept was an electroformed nickel plate. Paul had graduated from Portland State in Chemistry while I was there and went to work in Cathode Ray Tube manufacturing at Tektronix. I had met Paul while I was starting up the transfer storage tube in Tek manufacturing. Paul had been exposed to electroforming nickel mesh at Tektronix to build electron lenses in CRTs. Paul was a very creative engineer. The concept for fabbing the orifice plate was to build a steel mandrel that had the barriers and spacers etched into the mandrel. The orifice was formed on the surface by creating a twenty-micron thick photo resist pillar for each orifice. Each Mandrel would make about 60 orifice plates with break tabs so they could be assembled as a group onto a glass substrate which had 60 thin film circuits that would align with the orifice and then be scribed and broke apart.

My role with Paul was initially to just make certain his plans were consistent with the overall plan and to be a sounding board for discussing the obstacles he ran up against. The issue was to be able to plate a non-flat surface uniformly enough so the orifice all came out with a very tight spread of diameters. This was difficult. I found that Paul was creative enough that he could try a plating idea for a couple of weeks and if it didn't work out, he would dump the tank and start over with a different plating bath and agitation concept. And this happened several times which meant no real progress. So, one day I told Paul to pick the plating bath he thought had the best chance of success because we were not going to dump it again; rather we were just going to solve the obstacles as they came up, no matter how tough. We soon had working models and we were on the way. To give some idea of the difficulty let me tell of our alternate plan. We had not put all our hopes on Paul, but I had begun a search worldwide for plating shops that might do the type of thing we were doing. The best one I found was in Europe (I think Belgium) and we gave them $25,000 to build a device and give us a quote on doing the manufacturing for us. It turned out they tried but could not come close to the quality we required.

Another aspect of orifice manufacturing was the fabrication of the mandrel. The mandrel was a square plate of stainless steel that had the barriers etched in and some spacers etched in and for each plating had to have the orifice pillars exposed in the photo resist and developed. I hired Bill Boucher to develop these processes and will use an example to show my role. Bill purchased an etch machine to etch the stainless plates. It was an in-line system. The plates were coated with a photo resist that was developed away where the barriers were to be etched. These were placed in one end of the etch machine and came out the other end etched. Bill was having a problem with most of the mandrels coming out where some of the photo resist along the edges of the developed away areas had lifted part way through the etch process which resulted in the edge of the barrier not being sharply defined. He told me he had exhausted his ideas and was about to abandon the automated etching idea. I suggested we go down to the machine and observe while it worked and he could explain it to me. As he went through the description, I asked some questions and posed some possibilities and after we were probably a half hour or more into the discussion, we (mostly him) came up with a hypothesis. As the plates went through the machine they passed through several chambers, one rinse to start, then the etch, and then a couple of more rinses. These chambers were different baths under the path of the plates which was sucked up and sprayed onto the plates. To keep each chamber from being cross contaminated they were separated by flexible flaps. An etch solution etches down into the material but also etches laterally under the photo resist leaving a lip. It turned out the flap exiting the etch bath was dragging on the plates and catching some of these photo resist lips and lifting the photo resist and some of the material was etched before the rinse section had time to neutralize the etch material. By adjusting this flap, Bill solved the problem and was off and running. I felt my job as a project manager was to not tell engineers how to do their job, but to insure they had objectives that met our overall plans and also to use my experience to help them work through their obstacles.

The start up team for the ink jet project had been pulled from the liquid crystal display fiasco. One of these was a PhD chemist named Curt Sheley who had worked on developing the liquid in the LCD and was moved over to develop ink for inkjet and consequently ended up reporting to me. We were only planning on black ink and it had to be water based so the primary task was selecting the dye. It was important that the dye be safe (not a poison some kid could drink and die from), water soluble (although suspensions were in the future), reasonably opaque on paper, that it resist fading in normal lighting and that it last a reasonable time in sunlight. The task required, besides obtaining and screening the dyes, developing some of the tests to evaluate the different criteria. This was where Curt came up short. He knew his way around the lab and could come up with different inks, but he didn't grasp the 'developing tests' part. I leaned on him and helped him define his objectives. But my style of not telling my engineers how to do their jobs failed with him. He drug his feet on developing a test of sunlight fastness until I went into "back up" mode and told him to put some sheets of print on the roof and stay up there until he had measured how much they faded in a week.

He complained about me to Frank and I pointed out to Frank that he was operating as a technician, not as an engineer, and I planned to demote him to technician. When I presented this plan to Curt he was pretty upset and he proved me wrong by finding a job elsewhere. I added ink development to Niels' tasks and we moved on.

Niels other tasks were developing the methods we could use to measure print quality and other characteristics to compare different pen designs. Neils was up to the task. He was excellent at taking meticulous measurements and keeping impeccable records. He was relied upon by the whole team for keeping the official lab notebook. Everyone kept an individual log book but Niels kept the official record of all events. Niels worked on all the testing of different inks and also on an additive that would prevent bugs from growing in the ink over extended periods of time. The only problem I had with Niels was that Frank had treated him like a 'prima donna' and I didn't. His frustration with that grew and eventually he told me he wanted to transfer to San Diego. He did have some interest in San Diego but this was primarily a threat to get me to pamper him more. He was somewhat surprised when I told him fine! I will talk to managers in San Diego and give you a good commendation. He backed down and said he wanted to stay with the project until it was successfully in manufacturing. As a side note, I later helped Neils get a one-year assignment in San Diego and it worked out pretty well for him. We remained friends but not close friends.

When we neared week zero (the start up in manufacturing), we had most of the processes defined but did not have automated equipment on order to meet the demands of the production ramp. Pat Shelley and I made a whirl-wind trip to try to resolve this. We went to Palo Alto to visit Varian, to LA to Spectra Physics that was building a projection lamp for exposing photo resist that we thought might work for the orifice fab, we visited a company in Simi valley that was working on using cameras and computers to do automated measurements that we thought might work for measuring the orifice diameters and defects, we visited a company in Phoenix that was building assembly tools for liquid crystal displays that we were interested in for mating the orifice to the thin film substrate, and we visited a company in Albuquerque that made ultrasonic/sand devices for jewelry that we thought might work for making holes in the glass substrate. We ordered several pieces of equipment and some of them worked out well. The inspection machine we passed on and went to a sample inspection that worked well. Automated inspection of orifice came much later. The ultrasonic device was too slow and we ended up using a diamond drill on an automated x-y table. We bought an exposure system from Spectra Physics that used a point light source and the pillars that we exposed with it slanted a bit at the edges but were usable. The Spectra Physics relationship played a big role in making laser ablated orifice years later. The assembly machine from Phoenix worked well enough and evolved over the years to work very well for our particular application.

e

e

I forgot to mention, that while in Albuquerque at the Mariotts we had a fire in the hotel and had to evacuate without breakfast. Pat never wanted to travel with me again because I was anxious to get done as quickly as possible and get back home. He would have preferred taking more time and enjoying the sights. We had accomplished all of this in one week!

As we got closer to week zero the number of engineers grew dramatically. As some aspects grew too large, they were spun off from my group. The first was the Print testing group and then the ink development and, in the end, at week zero I only had the orifice plate. One of the last major projects was automated assembly.

I assigned several engineers, including Pat Shelley and Stan Hall, to determine how we should do the assembly. They ended up buying an assembly machine from Bodine, a company in Connecticut. It was a synchronous in line that did small tasks quickly and then stepped the parts to the next station. We had always thought of our program as like Gillette's razor blade industry where at one time they gave away the razors and made money on the blades. We thought HP should give the printers away and make the money on cartridges. The increase in revenue would follow a geometric progression since the first printers would keep needing replacement cartridges as well as the new sales.

My difficulties with Ernst continued. HP gave stock options to recognize contributions by engineers and managers and these were controlled at Ernst level. He knew my team had the toughest tasks and we had come through so he rewarded the engineers who worked for me but not to me. The closest he ever came to getting past his grudge came during the initial build of the printer, Thinkjet, for inventory to support introducing the product. We suddenly had a drop in print quality that was causing the print cartridge output to go so low we couldn't support the printer build. I was given leadership for resolving the problem. I pulled together five or six engineers I thought would have the best insight into this and they came up with a hypothesis that the resistors were overheating. Refill was driven by capillary wicking and overheating would have two deleterious effects, first it would create a larger than necessary bubble and blow the ink farther away from the resister and second it would leave so much residual heat on the resistor that the ink would not completely refill before the next firing. We were constrained by a voltage which was already set on the printers and by the power density on the resistor which if we changed would negate all reliability test results. So, I came up with the idea of making rectangular resistors that were the same length as the original (constant power density) but reduced in width (less total power,smaller bubble).

Bill Boucher modified the artwork by hand to make rectangular resistors in two versions, two thirds the width and one half the width. We ran three variations, the original resistor, the bold design (2/3) and the extreme bold (1/2). Both new designs solved the print quality problem and it was very clear we had nailed the problem. I wanted to run another experiment to find the limits but we were too far behind production and it was decided to go with the bold. An overnight modification of the thin film artwork and we were back in production the next day. The entire solution took less than a week. I passed Ernst in the stair well shortly after and he commended me briefly and reluctantly - eating crow is tough for all and impossible for the pompous.

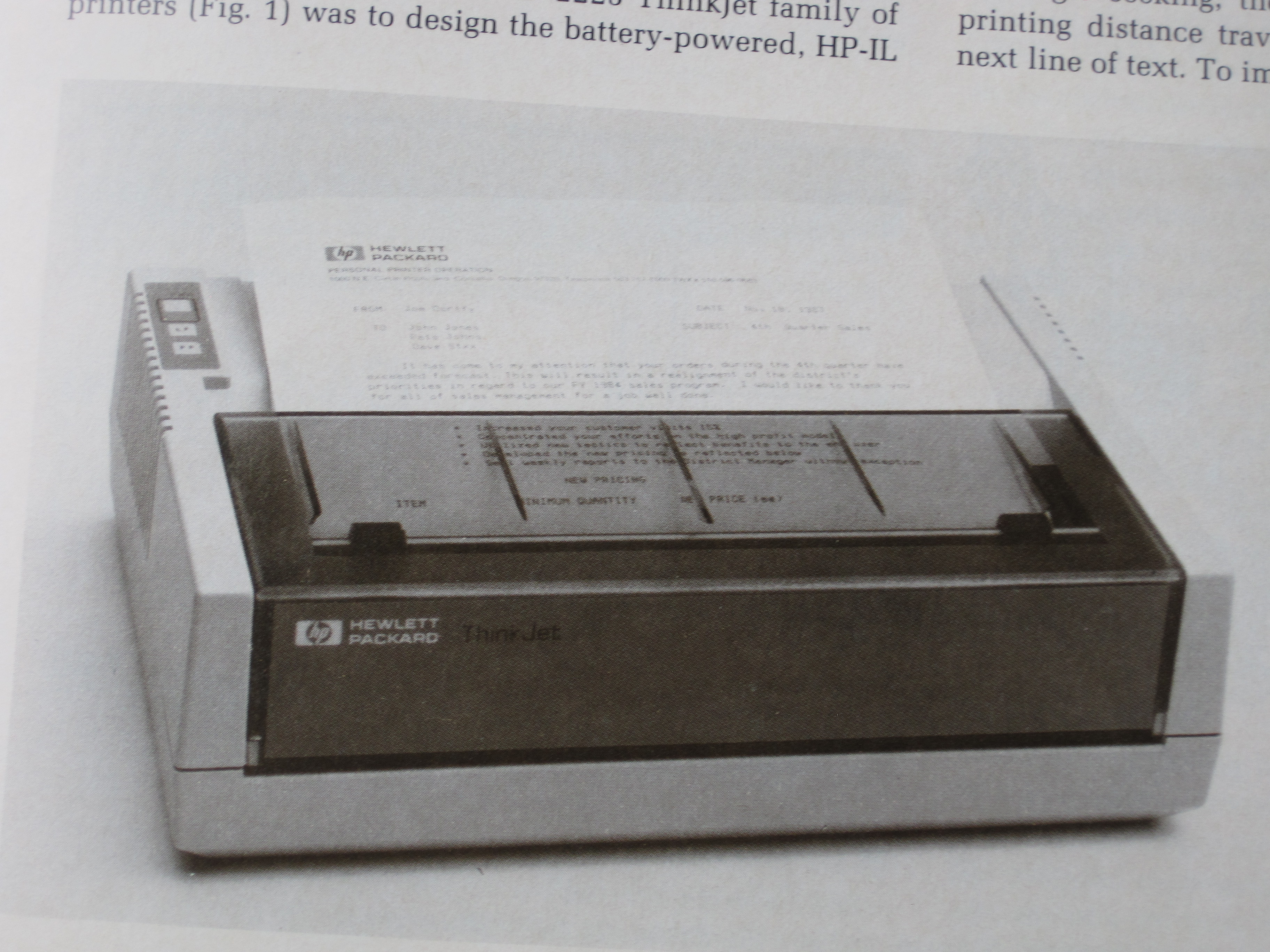

I have already mentioned the printer that the Corvallis division developed for our print cartridge called "Thinkjet". Shortly after the introduction of Think Jet, HP decided to put all of printer manufacturing in the Vancouver Division, so Think Jet was the last printer developed in Corvallis and we in inkjet began a long relationship working with Vancouver. This seems like a good time to talk about some of the organization changes that occurred in HP during these times.

One of the keys to success for HP was the fact that Bill and Dave made each division a business entity with its own market segment. They were independent and responsible for all aspects of the business including profit. As a result, over time several divisions developed printing technologies: San Diego (the x-y plotter division) developed fiber tip plotter pens, Loveland, CO (desktop calculator division) developed page width thermal printheads for printers for use with their programmable calculators (which became almost indistinguishable from personal computers), several Bay Area divisions developed impact printers for their product lines and the Boise Division which developed an extraordinarily successful OEM product line using the Canon LaserJet technology in joint designs. A precedent had already been set in the integrated circuit manufacturing. Due to the very high capital investment required, IC manufacturing was developed at only two sites: one in Palo Alto for general HP business and one in Corvallis for hand held calculator specific (NMOS and cutting-edge low power CMOS circuits). First the different impact printers were consolidated and Vancouver Division formed to be the printer division. Shortly after the introduction of Thinkjet, it became clear that the printing business needed to be managed at a level that could develop and coordinate strategies both of the printers and the printing technologies. The two major printing divisions, San Diego and Vancouver, as well as the technology development in San Diego and Corvallis and the LaserJet business were combined under a single manager who reported to vice president Dick Hackborn who had started up the Boise site and the LaserJet business. Soon after that Erst Ernie was dispatched to a position in VCD (to never be seen again by me) and Tom Haswell took his position as manager of inkjet technology in Corvallis. I never missed Ernst. Tom was never anything but positive with me; perhaps due to my befriending him when he came to Corvallis. He was responsible for the paths my career would take over the next few years.

When Thinkjet was introduced, teams of marketing and inkjet technologists were sent out to customers who had placed large orders. Ray Siuta and I traveled together and visited General dynamics (Dallas) and Rutgers (New Brunswick, NJ) and the HP field office in Paramus (NJ). Ray talked about marketing aspects and I gave simple descriptions of how it worked and the importance of sending us any failures for analysis.

The main feedback on inkjet was how quiet it was. You have to be in a room with impact printers to realize how important that was. In 1985 Epson dominated the printer business with their impact printers and within five years HP inkjet would take over as the dominant printer.

Marzio and his team had developed the thin film for our inkjet cartridge. All of the processes were modified versions of processes currently used in IC manufacturing and as such were not expected to be major problems. However, shortly after the introduction of Thinkjet the thin film process came off the tracks. The metal resistors and conductors were covered with a silicon oxide/silicon carbide layer to protect them from the ink. This dielectric began to lose adhesion to the metal and peel during subsequent processing. The result was that all production was suspect and the line was shut down. Tom called me in and asked me to go to manufacturing and direct the solution. I told him that Marzio had created the problem and Marzio should be sent to fix it. Tom understood the argument. The next day he called me in again and told me he had discussed it again with his R&D manager and Manufacturing manager (Frank and Greg) and they had both agreed I was the only one who they thought could fix it quickly enough and Tom really leaned on me to help him out. I requested some time to consider it, but I realized I really had no choice and the best I could do was come up with conditions which would increase the chances of success. The next day I returned to Tom with four conditions: first, that the thin film team under Marzio report to me in manufacturing until the problem was resolved and some of his team for an extended time after that. Second, that two engineers who were working on data collection software report to me and create a process control data collection system. Third that I could start hiring engineers to staff the thin film group in manufacturing after the R&D engineers were released. Fourth that I be given back my position in R&D once the problem is fixed. Tom agreed to all. I was back in Manufacturing. The thin film engineers from Marzio's group performed very well for me and we had the line back up and running before the sales of printers was impacted, barely. Some interesting tidbits from this exercise. First, the engineers working on data acquisition systems asked me what I wanted from them. I told them I wanted them to set up a system that would collect the data the process engineers considered critical for controlling their processes and every time one of these parameters went out of control a two by four would drop from the ceiling on the process engineers head and wake him up. They didn't accomplish that but they did set up an advanced process control data system that was the envy of even IC manufacturing.

I hired six process engineers over a six-month time period and many became outstanding contributors. All but one were college graduates with no experience. To train them quickly, I developed a routine of regular one on one meetings, I spent a lot of time in the cafeteria. I trained them in writing objectives, setting goals, and measuring progress. I also went through details of their plans and had them develop very specific steps for solving problems. An example was Glen Hopkins who had just gotten his masters degree from Oregon State in Physical Chemistry and who before I retired had moved up to one of the leading management positions in the TIJ business. One of the tasks I gave him was procuring one of the thin film deposition systems (I have forgotten just which one) but I wanted it to have automatic loading and unloading. This was being done in IC manufacturing so the system vendors had the capability but we were using square glass plates, not round wafers, so they had to do some pretty serious redesign. Like all vendors, they promised it would be no problem. Part of the contract we had agreed to with them was to demonstrate the tool at their site prior to shipment and Glen was sent to buy it off. He and I sat down and worked up a very specific plan for qualifying the tool and he took glass plates with him for the qual. He called me and they had some troubles in the qual run but knew what to do to fix it and he was planning on authorizing the fixes and shipment and heading home. I told him no, he should rerun the qualification just as we had planned and not leave or ship the machine until it passed. He was there for several days, they finally worked out the issues and shipped. It paid off in that he had very little trouble getting the system qualified for production in Corvallis.

I set aggressive yield improvement goals for the thin film team and I published a set of graphs that became infamous showing yields at each major process step and cumulative yield through the line. When I had a meeting with the team to set these yield goals, they had no idea about learning curves so I just picked the numbers. Glen was always pretty outspoken and he suggested the numbers were ridiculously optimistic and asked me where I got those numbers. I replied that I got them from experience, which he did not have. Years later when he was managing the intermediate assembly area and was setting goals, he related the story to his team and told them I was the best manager he had ever worked for. We did achieve the goals and they were not easy. All of those engineers except one went on to become solid contributors in TIJ. I suppose I should tell the story of the one exception.

Because I was trying to hire people quickly, I did more screening of candidates over the phone than I normally would. My opinion is that it is very difficult to assess potential through conversation and impossible without face-to-face conversation. One of the candidates was a girl named Shelly who was doing post graduate work (I forget which University). Her resume' said she had experience in sputtering, so I called her and I asked her some questions on sputtering that I thought someone working in the field should know. She didn't so I told her I would not bring her in for an interview. A couple of days later she called me up and she had researched the questions, knew the answers and impressed me with her initiative. So, she came in and interviewed and impressed the interview team and we hired her. She was a chemist and I assigned her to the photo processes. We later were having a problem with defining the resistors. The last step was to etch a rectangle of the aluminum layer away exposing the Ta: Al resistor material. The etch left rounded corners and was causing the center area of the resistor to be hotter than the ends. I suggested to Shelly that she try modifying the artwork to compensate by removing some of the photo resist in the corners. She dubbed it the 'cat ears' mask and it worked well. So, of the group I hired to get thin film up and running, one turned out exceptional, one good and the rest very good engineers.

Several months after I had gone to manufacturing, Tom offered me an opportunity to come back to R&D. I told him I had too many things incomplete and requested I stay longer. He agreed but when a year was up, he called me in and said I either had to come back then or he would not guarantee it in the future. I decided to stay in manufacturing and I never returned to R&D. Some time after that the manufacturing manager, Greg Merten, decided to create an engineering section and began the search for a manager for the section. I was enjoying the Project Manager position and the training of new engineers and did not apply. However, I became concerned about who was applying and the fact I would end up working for them, so at the last moment I threw my name in and I was promoted to section manager.

There essentially was no section. There was the thin film engineering group and several other engineers assigned to specific processes, such as orifice plating, testing, assembly, and thermal printheads which were still around. The organization was not set up for a product line that was growing as a geometric progression. I promoted a new thin film manager, Bonnie Severy. She was a good manager but unfortunately, she later let politics get in her way. She did a good job for me and I focused on the remaining engineers. I started a product engineering group, initially hiring one engineer, Doug Ullmer, and then adding a second. This was our first experience with product engineers in TIJ and I worked with Doug to define what his assignment was and the metrics for success. I ended up with four engineering groups: thin film, orifice, assembly and product. I then worked on a yield improvement program since the cumulative yield of St Helens from start to finish was extremely low. I set goals with each project manager and insisted they set goals with each engineer in their group that would accomplish the overall goals. Then we had goals each month for the cumulative yield and when we met these, I took the entire section out for pizza and beer and then gave them the rest of the day off. This worked wonders and we met every monthly goal after that.

One of the unique things about the TIJ success was the collaborative work between R&D and Manufacturing. Murch of this was due to Frank and Greg focusing on the project being successful and doing whatever was necessary for that. However, an interesting anecdote occurred regarding R&D verses Manufacturing. John Young, then the CEO of HP, held a meeting in Corvallis that had a twofold purpose of a regular HP upper-level corporate management meeting and a chance to review what was going on in Corvallis. Tom asked me to give a presentation on the production engineering work in TIJ. At this time, the company was looking at the pay of engineers. Engineers at that time were paid on what was called the "68 curve". This was essentially three levels of engineers: 6,7, and 8. Many of the top managers were selected from R&D section managers and had started in HP as R&D engineers and they had a pretty high opinion of R&D's contribution. Some of the discussion was that engineers in manufacturing should be constrained to a "67" curve since their contribution was not as great as R&D. My recent experience had given me a different opinion and, in my presentation, I talked about the work that the production engineers were doing in TIJ and I showed a slide which got a lot of attention and in which I defined: " The Production Engineer is the one who takes a once in a lifetime phenomena that the R&D design engineer thought he observed once, and makes it occur every day on demand." After the meeting, I led the managers in a review of our automated final assembly on the Bodine machine. One of these managers made the comment that the machine was like an oil well and every time it moved, 7$ pumped out. ($7 was price of St Helens cartridge initially). He later pulled me aside and complimented me on my slide and said he agreed and thought it would help in the discussions on engineering pay.

After the introduction of St Helens, R&D started working on a next generation thermal inkjet. I participated in the meetings to define what it should be, but not in the design. The agreed upon concept was that it had to be higher resolution and higher speed. The implications were pretty big, we had found we were limited to St Helens printing speed on the glass substrate and we were limited in resolution by the process selected for making the orifice plate. The new pen, dubbed Stanley because the pen body shape looked like the head of a Stanley hammer, would end up being built on silicon wafers and the orifice mandrel process would be completely revamped. The print speed was measured in maximum frequency at which any one nozzle could be repetitively fired. On glass the heat build up and subsequent refill times limited the frequency to under 2khz. With silicon the frequency was easily doubled. Cheryl Katen was brought in to Frank's R&D group as the program manager for Stanley.

Because of cross licensing agreements that HP had with Canon that had been crafted for the Laser Jet business, we in TIJ also had to share our work with Canon. Canon had 'invented' a TIJ about the same time as Jon Vought and used the same in-line design. They had stuck with the in-line design and had product prototypes in 1984 when we introduced St Helens. Canon sent teams of engineers to Corvallis to observe what we were doing and we sent a contingent to Canon. One of the things that came out of this that impressed me was a color picture Canon claimed they had printed with a color inkjet. It was good. In a meeting that Tom Haswell had with the key players in his TIJ organization he asked where we thought we should be going with the technology. I was the lone voice saying that our thrust should be for photo quality color printing. That was a huge step from where we were or were planning on going in the next generation. I think the only one who thought I was not crazy was Tom. Tom even more so a short time later when HP manager for all printing and vice president, Dick Hackborn, declared that for TIJ to be a viable technology it must develop plain paper printing of both black and color! Shortly after this a new program manager in R&D, Ron Prevost, began a project to build a color cartridge (Kukla) using the second generation (TIJ2) technology.

By 1987 my production engineering section was very solid and the strategy was to transfer the TIJ2 frontend processes to manufacturing before week zero. Cheryl's strategy for the final assembly was to design the assembly tools and processes within her team and move the team to manufacturing at week zero. Stan Hall was project manager for the final assembly under Cheryl. Stanley week zero was in the fall of 1987. The plan was to ramp the cartridge production up and introduce the printer, Deskjet, in early 1988. A couple of things happened to put the plan in jeopardy. First, the Vancouver Division plan for Deskjet was that it would be priced at $1000 and would sell 200-300 a month. Dick Hackborn told Vancouver that if they wanted to be successful in the printer business, they needed to price the Deskjet below $500. After some soul searching and redesign, the printer was slated at just under $500 and projected to ramp quickly to 1000 units per month. Because of the geometric progression that cartridge demand followed, this was a huge increase in the TIJ ramp. The second event was that the production line designed by R&D for final assembly was a serial line of about twenty independent tools that had an in-line conveyer moving the parts between machines. There were no planned queues (some one had read Toyota's book on JIT but didn't understand it) and the probability of those machines all being up at the same time was near zero in the beginning and never real high. Tom was not happy.

Sometime in late 1987 Tom called me in and requested that I move to final assembly and take over managing the introduction of Stanley. I gave the same answer I had given when asked to go to manufacturing to fix thin film. I got a similar response. I pointed out that my experience was in process development not assembly but Tom insisted I was the only one he trusted to get it done. I accepted, I doubt I had a choice, and I made only one request and that after a couple of weeks: that the product engineering manager, Paula Kanarek, move to manufacturing and report to me until I could hire a product engineering manager. Paula was not enthused but agreed. She did a very good job for me but kept reminding me I was supposed to hire someone to replace her until I hired Mike Hafner. Hiring Mike was an interesting story that causes me to digress.

Greg had decided he needed to hire a Materials manager. This task had been done by several people who reported to the production manager, Ed Schwallie, but Greg wisely wanted more leadership in this area. Greg formed an interview team that was just he and I and Ed. The candidates were reduced to two, one of which was Mike Hafner. I had known Mike for several years and worked with him on a calculator printhead application. In the meeting to select the Materials Manager, I was for Mike and Greg and Ed were for the other candidate (name left out to protect the guilty). So, Greg decided on his choice and I requested that Mike be offered my Product Engineering manager's position. Greg agreed, Mike accepted and Mike turned out to be an extraordinary manager and even a favorite of Ed's. The material manager selection did not work out and after a few frustrating months he was replaced by Dave Young, who was excellent.

Stan Hall was a very good project manager but he was overloaded and did not recognize it. It caused some hard feelings when I brought in Paula and took the product engineering team from him, but it probably saved his career and he and I had many years of working together successfully. So began my training in assembly.

Historically, designing tools in house for assembling HP products had been a competitive advantage. Every division had a rather large tool shop and every product team had tool design engineers. So, the Stanley assembly line was doing business as usual. However, HP's most successful products in the past were only a few hundred a month, they had never been in the business of building a million of something in one month. The design of an assembly line was a mathematical problem and I became a student. Greg had simplified his group creating a production manager, Ed Schwallie, and a Manufacturing Engineering Manager, me. As such I was responsible for assembly tooling. My team had come up with a concept for building Stanley on high-speed lines and we dubbed it AMPAL (automated manufacturing pen assembly lines). I had pitched this concept and set some expectations that we could get a million pens a month from our machines. I read the Toyota story and pronounced JIT as not 'just in time' as Toyota claimed but rather a 'Japanese insidious trick'. JIT was advertised to have eliminated queues but, in fact, Toyota had eliminated inventory in their assembly lines by simply transferring the queues to their suppliers. They demanded constant availability and the only way the suppliers could guarantee that was to have inventory ready. Successful assembly is not about eliminating inventory, it is first about maximizing throughput - and only then with minimum work in process inventory. My management team (three of my four PMs had been tool design engineers and the other had a soft spot for tooling) had grown up the HP way but we were all enthralled with how well the Bodine machine for TIJ1 worked. Stan, who had been a key player in getting the Bodine, had dismissed it for TIJ2 because even Bodine had said the assembly was too complicated.

I convinced both Greg and Tom that we needed to do something different. We needed to do a world-wide search of automated tooling vendors to find companies whose expertise was in automated tooling – who did it for a living. We visited vendors in groups of two, a PM and a tooling engineer. In a few cases I went along. I will give some details on those.

We went to Japan and visited the Seiko plant where they were assembling watches. They were into robotics and wanted us to buy robots for our assembly. We visited the Panasonic battery plant where they were building alkaline batteries and were setting up a line to build Lithium batteries but they were keeping it pretty secret. The alkaline battery line was running at 600 a minute and the fact that they had queues at every step affirmed my thoughts on assembly. They used some clever ways of moving parts that fast (vibrating channels) but the main thing was that there was always one ready to move as soon as the one in front moved. We also visited a plant that was making VCR's and the main point of interest was their process control techniques. The operators did almost all of the process control charting by hand. The advantage of this is that it is real time and the one who needs to know, knows! They were also posted on the walls so anyone passing by, like a supervisor, knew.

We visited a German company that was assembling quartz tube heaters. Actually, we were taken there by the company that had built the assembly tooling. They turned out to be one of our choices for a future assembly line but the management of the larger corporation decided just as we were ready to start them up to shut down that part of their business. We also, same trip, visited a Swiss ball bearing factory. The company that had built their automated tooling became one of our suppliers when Kukla assembly was automated.

Another trip that I went on was to visit an automated machine supplier in Erie, PA. This company had built assembly lines for large commercial light bulbs. The tooling was extraordinarily heavy and not at all suited for the fast assembly we were looking for. However, one of the managers took us down to an island (Presque Isle) near Erie where ships had been constructed that were used by Admiral Perry in the battle of Lake Erie in the war of 1812. The history was more interesting than the tooling.

There were a number of other vendors we evaluated and when it was all done, we selected a company ( Midwest tooling in Chicago). The company was owned by a somewhat eccentric fellow who had been in the business for years. He had a strong engineering group and broad diversity of experience including spray heads for sprayer bottles and air bag units for cars. We formed a long-term relationship with them that was very beneficial for both companies. But now I will pick up the inkjet story again.

One of the complaints we heard about the Deskjet printer which was introduced in 1988 was that the cartridge did not have enough ink – it emptied too soon. I understood later that this will always be the complaint when the replaceable costs a significant amount. We were selling the Stanley pen for $8. But marketing never learns these things because someone else must solve the problem. So, we had competing programs. Manufacturing wanted to increase revenue by productivity. R&D wanted to double the amount of ink from 40cc to 80cc. Tom Haswell had been replaced by Dana Seccombe as the worldwide TIJ manager. I never knew why Tom was replaced. Tom retired from HP. Anyway, I had gotten to know Dana pretty well and we got along fine.

So, R&D began a project to double the amount of ink. The theory being if we could double the ink and raise the price to $12.50, we could make the customer happier and we would increase our profit margin, which was already pretty good at $8. R&D came up with a scheme of springs and concentric cylinders that from a manufacturability perspective was hopeless. As the Manufacturing Engineering Manager, manufacturability was my responsibility. I argued that it would be better to maximize revenue by automating the lines of the rather simple Stanley design, which we were in the process of doing, than change to a complex design that might increase profit margin but at a lower revenue. With the simpler design I was convinced that profit would be increased by our plan over the redesign. Dana requested his staff, with him not present, make the decision. The first day of the meeting, Greg was gone and I sat in and held my ground. The next day Greg returned and I briefed him on what had gone on and he stated that he was in favor of the redesign. So, I deferred. They decided on the redesign. Dana knew where I stood and called me and asked me if it was a good decision. I told him it was a good decision in that we needed the issue resolved, but that it was not the best decision. Time would confirm that I was right. But the immediate task was to be successful. So, I requested that one of my Project Managers and his team transfer to R&D and help with the redesign and transfer back into Manufacturing when the design was ready to transfer. It was agreed.

Some discussion of the design challenges. Most of the challenge was around backpressure control. As I discussed earlier, the TIJ1 cartridge, dubbed St Helens since it was conceived the same year Mount St Helens erupted (1980), used a rubber diaphragm (ala the old fountain pen) to establish a negative pressure of around 2 inches of water. The TIJ2 pen, dubbed Stanley, used foam (ala San Diego plotter pens). The foam was filled (saturated with ink) and then a little was pulled out and the capillary force of the back exposed surface of the foam created a slight back pressure that remained relatively constant until the foam was emptied. (Note: this requires that the back surface is exposed to atmospheric pressure.) The capillary forces of the channels within the printhead were sufficient to draw the ink out of the foam. Also, it was important that the design be robust enough to withstand shipping in airplanes without leaking ink. It was likely that a Deskjet printer, with an open ink cartridge would be taken on an airplane and if it dripped ink the owner would be very unhappy. Both the St Helens and the Stanley designs were able to withstand the temperature and pressure excursions that might be encountered. So, from an assembly tooling perspective the Stanley design was simple and robust and ideal.

As stated earlier, the first design from R&D was rejected as not manufacturable. The R&D manager placed his designers under the PM from Manufacturing Engineering, George Custer (distant relative of the George Armstrong Custer and similar hair color). I don't remember the specifics of the next design, although I knew it very well at the time. I will just say that it involved an air bag that expanded as the ink was dispelled and maintained negative pressure at the nozzle. The first challenge I wanted to see it pass, besides normal functioning, was environmental tests. We enlisted a driver of an ice cream truck to haul some of the pens around as he delivered ice cream. We also established some in-house tests of pressure and temperature chambers. The design had troubles right off. The design team was quite creative and they were able to come up with possible solutions to each new failure but each time it added complexity. I thought we needed a parallel path just in case. George was adamant against it, stating that putting resources on an alternate design would reduce his chances of fixing this design. However, it turned out he had three engineers working on possible tooling designs for the assembly of his team's design. We already had the tooling company working on designing our first automated assembly line and any design changes meant changes to their design and George was trying to avoid delays. But I insisted he take these three engineers and put them on exploring alternate designs. As the pen design required more and more modifications, it became very convoluted. Meanwhile the three engineers on the alternate path had gone around and talked to any engineer with an idea and had come up with a simple idea of a spring-loaded ball against an orifice. They had built some prototypes and demonstrated preliminary printing quality and passed testing in various environmental conditions. It looked too good to be true. It was very simple and seemed to be very robust. I decided to propose the change in path to Dana's staff. Dana was worldwide manager of all inkjet operations and, as such, managed the San Diego Inkjet operation. Greg was acting as a worldwide production manager and, to keep balance, Dana had put the San Diego R&D manager over all R&D. He took the same line that George had taken and claimed we were sabotaging the R&D design by pulling people off and we could probably have fixed it if we just focused on it. I had the engineers in charge of the two designs go through what the design looked like and it was apparent to any objective technologist that the alternate design was far superior. It was certainly clear to Dana and the change was made. It was probably good I had no aspirations to go back to R&D. We did continue to use the concept of the bags from the original design to create negative pressure as the pen emptied. The design allowed twice the amount of ink (40gms) in the same pen body dimensions as the original Stanley design. Several years and several Deskjet products later, this ink jet cartridge became the highest annual revenue product in HP's history. And it could have been higher with the Stanley design. This product is a good lesson in business: HP had historically measured a division's success by its per cent profit. Most successful products in HP had nominal revenue and profit margin was a good measure of the design. But with inkjet we moved into mass volumes and the old metrics did not work. The decision to change the Stanley design, although partially due to complaints about replacement rates from the field, was primarily made by Skip (Corvallis R&D Manager) and Greg based on the old axiom that the higher the profit margin the more successful the product, and thus the managers. I tried to look at it from a maximum profit dollar perspective. The simpler Stanley design would be easier to automate and consequently manufacturing costs would be lower and the Stanley design would also require more pens. My analysis said that Stanley would have brought more revenue, more profit dollars, but a smaller profit margin. Hence, I had told Dana earlier it was a good decision but not the best decision. The marketing driven reduction of ink well below 40cc in future pen designs has made moot the argument for customer satisfaction through more ink

I will now go back and pick up the automated tooling project for this new pen. As I stated earlier, the historic HP technique was for a tool designer to have a step or more of the assembly process and he designed the process and created the tool. Our approach was to have Midwest designers work with our engineers in the design of the assembly process and then Midwest design and build the tooling. We, the managers, established some aggressive goals for cycle time, uptime and yield. I have forgotten what they were exactly but I know the cycle time was very aggressive, around three seconds (based on assumptions to produce a million pens a month). I remember a few years later an engineer on the Monet line dumped on me that I was the cause of all the problems they had with startup because I insisted on an unrealistic cycle time (it was the same as this first line). The Monet line was built by another company (in Nashville) and their tooling concept was much bulkier than Midwest and the cycle time was more of a challenge for them. Now back from the digression.

The Midwest line consisted of four modules and I had one of my three project managers (Jim Guynn, Larry King and George Custer) responsible for each. Between each module was an accumulator (queue) that could collect up to one hours production buffer if one of the downstream modules was down (sayonara JIT). The line was built at Midwest and qualified before being shipped to Corvallis. We sent a whole team of production operators to Chicago to run the qualification. One of my project managers, Jim Guynn, was also assigned as the Midwest liaison and he had worked out the qualification plans with them. However, when the time came for the qualification, Jim was sick, and I went in his place. We spent about a week qualifying and when that was a success, we had a corporate jet fly us from Chicago to Corvallis. We celebrated on the plane and called Jim to tell him all the details. This line became the model for all of the lines built in the future and was very lucrative for HP.

Gary Egan had been hired and brought to Corvallis to be the worldwide manufacturing manager (i.e., of Supply Chain and Production). He and Greg and I went to Midwest to discuss future business. In the past, HP had held their product volume forecasts very 'close to the vest'. On the way out on the plane I proposed to them that we show them a graph I had made up which gave the five-year forecast for Midwest machines we would need. Gary was somewhat reluctant but agreed. In the meeting with Bob (Midwest owner) it went over really well and established an open friendship between Bob and I that was beneficial to us both in the future. Bob sold his company and bought a fifty-foot yacht and retired about the time I retired. His machines were instrumental in TRIAD becoming the highest revenue product in HP history.

One little anecdote that demonstrates the benefit of the partnership with Midwest. A critical part of the design were the air bags that expanded to allow the ink to drain while maintaining proper backpressure. Since a failure of these bags would be disastrous in the field, we had decided that we would do 100% testing of all air bags on the assemble line. Making bags was something we had no experience in making in high volume. It was part of George's responsibility and he found a company in Marin County that was making bags for medical field. i.e., bags for IV's. The deadlines for progress on a machine to make these at a rate of several hundred thousand a month kept being missed. I became concerned and made a trip down there with George. It was obvious to me that this small company was experienced at doing quality bags in low volume highly manual processes. They were completely out of their area of expertise. However, both the owner and George were optimistic, so we agreed on a final deadline which would be 'fish or cut bait' time. Meanwhile, I talked to Midwest and assigned two really good young engineers (Gary Tarver, one of the three who had worked on the alternate pen design I discussed earlier and Sherman Wong, both excellent tool designers) to work with the Midwest designers to develop a method of making the bags using Midwest type automation. We ended up 'cutting bait' on George's plan and Midwest put a high priority on having a module in time for the start-up; which we did.

These pen assembly tools we purchased from Midwest for $4.5M each. They met the goals for productivity and gained a lot of attention from HP managers. John Young who had taken over as CEO from Bill Hewlett came to Corvallis to check it out. Greg got his share of attention but asked me to give John a tour. I took my three PMs with me and they were quite willing to do as much of the talking as they could. Gary Egan added to my Manufacturing Engineering Manager duties that of overseer of worldwide inkjet high volume automated tooling. The Production Engineering Manager, (Joe?), from San Diego came up and spent three months with his desk next to mine so he could use our experience to develop a line for the next San Diego product (Calvin). Their product was a more complex design and the line ended up costing around $20M. The Calvin line had four pens, black and three different color pens.

Corvallis was developing a tri-color pen called Monet to be paired with a new 600 dpi pen called Hobbes. R&D had decided to use the Calvin pen body design but with foam for ink containment. The Calvin ink containment was a rectangular shaped box with a bladder and metal spring ala the old fountain pen. TRIAD had developed within Corvallis a unique R&D and Manufacturing Engineering relationship. However, this pen was to be designed by San Diego R&D and built in Corvallis. So, our Manufacturing Engineering took over responsibility for making the concept of the ink containment system work before the transfer of the product to production. So, George Custer was assigned to Monet with responsibility for first the ink containment design and then the automated tooling line to assemble it. From my perspective, the Monet concept had two problems from the start. First it was huge to achieve capability of 40cc ink for each of three colors. Second it was the shape of a double deck of cards, i.e., flat rectangle which meant that the longest distance of a column of ink in the foam was very long. The capillary retaining forces in foam could be controlled somewhat by the foam density but only within a small range. I suggested that George test this thoroughly for robustness in different environmental situations, but he waited too long and ended up doing pen body changes that had dramatic impact on the automated tooling which was in progress in terms of redesigns and expense. Another slight digression now.

Gary Egan had agreed with Dana to take the Manufacturing Manager position for the inkjet business for a time to prepare Greg for the job. At this time, Greg's organization was Ed Schwallie as production manager including product and sustaining production engineering and myself as Manufacturing Engineering Manager including product improvement projects and new product introductions. He decided to divide his organization up by product lines, with Ed having all black pens and myself all color pens. Each of us would have our own production, product engineering, & production engineering. Manufacturing engineering was reduced in scope and Jim Guynn became the manager. The two-color pens at this time were Kukla (a tri-color pen in a TRIAD pen body) and MONET which was ready to start up in production. I will cover separately a couple of memories of these two products.

We were at this time starting up production in Puerto Rico. HP had an operation in Aguadilla on the west coast of Puerto Rico and the products they had been building were dying so they enlisted us to put some of our production there. Greg was convinced by Ed that we should start with a TRIAD line. My pitch had been that we should start with something simpler and lower volume like a Kukla line. I was convinced that the TRIAD line was too complex for a team that had no thermal inkjet (TIJ) experience or any experience with high-speed automation. I finally went to Gary Egan and presented my opposition to the plan. He agreed with me and after he talked to Greg, he agreed also and the plan was changed. Later when Greg thought Gary was going to retire and he was heir apparent, he told me that there was not a place for me in his new organization. Fortunately, Gary stayed on longer than anyone thought. So, we moved one of my Kukla lines to PR and Bob Conder, one of my managers, went to Puerto Rico to manage the TIJ operation there. He and I sat on a porch of the "Happy Belly" bar on the beach in Puerto Rico and outlined the Color Product line strategy.

In Corvallis we were trying to start up Monet production. I returned after having been out two months for my bypass surgery, so I wasn't my mellow self. George had overall responsibility for this but it soon became apparent the problems were too much for George to handle. I took over a weekly meeting of all the key players from all areas of manufacturing and we discussed the issues and who was responsible to resolve them and what they were committed to. The assembly line was massive and complex; difficult to get running and seemingly impossible to keep running. The product could not pass environmental testing. So, the weekly meetings became pretty testy when they discovered I expected their commitments to be met. This triggered responses like I mentioned earlier by an engineer who claimed the whole problem of the line was mine for insisting on such a short cycle time. Several engineers on George's team never liked me after this (the lead engineer transferred to Vancouver Division) but eventually, miracle of miracles, it came together and the product was introduced successfully.

Gary Egan was instrumental in starting up an operation in Ireland. He assigned Dave Young, his Supply Chain Manager, to manage the start up. Then Gary retired and moved to Arizona. Greg took his position as world wide Manufacturing Manager and posted the Supply Chain Manager and I applied. I suspect through Dana's influence, I got the job.

CH7_Story > ^b417a7